This column introduces the single-core, highly flexible robot cable UL11527 AWG28 (Ø0.60 mm) stocked and sold by our company. The article covers product specifications, the technical background behind its structure, a comprehensive list of potential applications, implementation notes, and demand outlooks for the next 5, 10, and 30 years. Sources are provided for key technical facts.

◇Product Page – Available from 1 m Cut Lengths

UL11527 AWG28 Flexible Wire for Moving Parts – Ø0.60 mm (White / Black)

https://nisho-en.ocnk.net/product/168

Product Overview (Key Points)

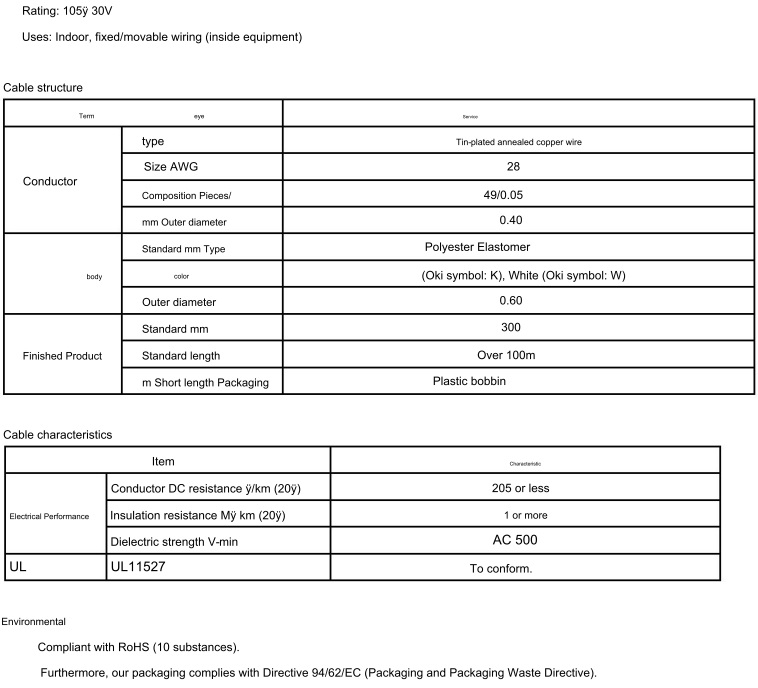

Product Type: Single-core wire used in OKI’s robot cables (core wire for the ORP-30F series)

Standard / Type: Conforms to UL11527, equivalent to ultra-thin AWG28

Insulation Diameter: Ø0.60 mm — extremely thin outer insulation (nisho.ocnk.net)

Conductor: 49 strands × Ø0.05 mm (49/0.05), contributing to superior flexibility (nisho.ocnk.net)

Insulation Material: Polyester elastomer (FRPEL10/U) — elastic, flexible insulation (nisho.ocnk.net)

Rating: 105°C, 30 V, RoHS2 compliant; suitable for short-run signal or low-voltage wiring (nisho.ocnk.net)

Stock & Supply: Available in white and black; sold in 1 m units (standard 300 m bobbin) — ideal for prototypes and maintenance (nisho.ocnk.net)

Technical Explanation — Why This Structure is Suited for Moving Parts

1. Flexibility from the 49/0.05 Multi-Stranded Conductor

Using many extremely fine strands distributes bending stress along the wire length and greatly improves fatigue life during repeated flexing. Even at the same AWG28 cross-section, “more strands = higher flexibility” is a well-established principle in dynamic cable design (okidensen.co.jp).

2. Benefits of Polyester Elastomer Insulation

Polyester elastomers exhibit strong elastic recovery, preventing deformation and abrasion during repeated bending. When combined with the robust design used in ORP-30F series cables, the insulation provides excellent heat and oil resistance—an advantage in industrial environments (okidensen.co.jp).

3. Design Freedom from Ultra-Thin Ø0.60 mm Insulation

Such a small diameter eases cable routing in narrow spaces, compact joints, miniature mechanisms, and dense connector housings. Designers can benefit from easier wiring paths and reduced mass for moving modules, enhancing motion response (okidensen.co.jp).

Comprehensive Application List (as Exhaustive as Possible)

Applications are grouped into “current/typical uses” and “technically feasible extensions.”

A. Industrial and Robotics Applications (Mainstream Uses)

Internal wiring in robot arm joints (sensors, encoders, limit switches, heaters) for reciprocating motion (okidensen.co.jp)

Signal wiring inside cable carriers/drag chains (okidensen.co.jp)

Sensor-to-controller wiring such as proximity sensors, encoders, and temperature sensors — all requiring flexible, repetitive motion tolerance (okidensen.co.jp)

B. Drones, Aviation, and Mobility Systems

Gimbal wiring for drone-mounted cameras/sensors, where lightweight and tight routing are essential (nisho-en.ocnk.net)

Wiring in autonomous mobile robots (AMR) for movable sensor mounts and compact actuator connections

C. Medical and Care-Assist Devices

Actuator and sensor wiring in surgical-assist robots and medical robotic arms where compact, highly reliable wiring is required

Flexible sensor/drive wiring for wearable medical assist devices or exoskeletons that must follow human movement

D. Consumer and Small Electronics

Internal flexible wiring in AR/VR headsets (folding/rotating mechanisms)

Wiring in handheld cameras, mini gimbals, and robotic toys

Moving-joint wiring in household robots such as cleaning and serving robots

E. Laboratory Automation and Research Equipment

Compact automatic pipetting devices and sample handling modules requiring repetitive motion and miniaturization

Flexible wiring for precision movement actuators within micro-automation systems

F. Other Specialized Applications

Movable wiring in optical mechanism assemblies (aperture and focus control)

Internal wiring for precision measuring devices with rotation or tilt motions

All of the above share common requirements: low voltage (30 V or below), short wiring length, and repetitive flexing within limited installation space.

Connector Compatibility and Implementation Notes

Connector Compatibility

Common compatible connectors include:

JST ACH / SACH series (AWG30–28, insulation Ø0.50–0.63 mm)

Hirose DF52 / DF57 / DF58 series for compact wire applications

Always verify the connector’s “applicable wire range” and the terminal’s conductor and insulation crimp dimensions (JST Manufacturing).

Crimping Considerations

Ultra-thin wires require precise terminal, die, and tooling selection. Incorrect crimping will lead to poor electrical contact or insufficient pull strength. Proper strip length and crimp height must be validated through testing (JST Manufacturing).

Harness Design Notes

When bundling multiple single-core wires, carefully design stress relief, sleeve selection, cable tie locations, and slack loops. For cable carriers, evaluate abrasion and consider additional sheathing.

Operational Verification

Before mass adoption, perform:

Flex-life testing

Pull-out force tests

Environmental tests (temperature, oil, chemical exposure)

Even though the ORP-30F family is designed for dynamic durability, real-world conditions must be verified (okidensen.co.jp).

Benefits Summary

Compact Routing: Ultra-thin Ø0.60 mm insulation enables efficient wiring in dense connectors and confined joints (nisho.ocnk.net)

Excellent Flex Durability: 49/0.05 stranding + elastomer insulation ensures long cycle life (okidensen.co.jp)

High Temperature and Oil-Resistant Variants: Available within ORP-30F product series (okidensen.co.jp)

Easy Small-Lot Procurement: Stocked for 1 m minimum purchase—ideal for prototyping, maintenance, and engineering builds (nisho.ocnk.net)

Practical Notes (Risks and Mitigations)

Voltage/Current Limitations: Rated for 30 V; unsuitable for power lines or high current applications (nisho.ocnk.net)

Mechanical Abrasion: Use sleeves or guides in environments prone to friction

Crimp Quality Control: Avoid conductor splay or oxide formation by strictly managing crimp processes

Environmental Limits: For harsh chemicals, strong UV, or extreme low temperatures, perform material testing and consider alternate sheathing (okidensen.co.jp)

Market and Demand Outlook (Evidence-Based Forecast)

5-Year Outlook (to 2030) — Growth Phase

Demand is expected to rise with the miniaturization and diversification of drones, service robots, and industrial robots. Ultra-thin flexible cables such as the ORP-30F cores are already expanding in product lines (okidensen.co.jp).

10-Year Outlook (to 2035) — Cross-Sector Expansion

Adoption is likely to increase in medical devices, nursing/assistive tools, wearables, and laboratory automation. Continuous connector miniaturization (finer pitch) will support steady growth (HIROSE).

30-Year Outlook (to 2055) — Restructuring but Persistent Need

Wireless systems and flexible printed circuits (FPC, conductive polymers) may replace some traditional wires. However, robust physical wiring will remain essential for power distribution, high-reliability interconnects, and harsh-environment systems. The market will evolve, not disappear (okidensen.co.jp).

Implementation Flow and Support

Sample Procurement (1–5 m):

For mechanical routing tests or flex/pull tests. Small-lot stock allows quick delivery (nisho-en.ocnk.net).Connector/Terminal Selection Support:

We provide selection guidance for JST, Hirose, and other compatible parts (JST Manufacturing).Harness Design Advisory:

Recommendations for bundling, strain relief, protective materials, and routing strategies.Mass Production Support:

Stable supply in bobbin units (300 m) and inventory planning proposals (nisho.ocnk.net).

Conclusion

The OKI Electric Cable UL11527 AWG28 wire (Ø0.60 mm, 49/0.05, polyester elastomer insulation) is an exceptionally thin yet highly flexible single-core conductor. It satisfies critical design needs such as compact routing, low mass, and long flex life—making it valuable for robotics, drones, medical devices, wearables, and laboratory automation.

When considering adoption, confirm voltage limits (30 V), crimping compatibility, and connector requirements, and conduct appropriate evaluation testing. Sample provision, connector selection, and harness design support are available through our trading company (nisho.ocnk.net).

UL11527 AWG28 Thin Diameter φ0.60mm White 300m Bobbin

UL11527 AWG28 Thin Diameter φ0.60mm Black 300m Bobbin