― Application of UL11527 AWG28 φ0.60mm for Next-Generation Devices ―

1. Background: Increasing Demand for Miniaturization and High-Density Wiring

In recent years, the trend toward miniaturization and weight reduction in electronic devices has intensified, along with a growing need for high-density and reliable internal wiring. In compact applications where flexibility and space-saving are essential, the combination of ultra-fine flexible wire and low-profile board-to-wire connectors is becoming increasingly important.

In response to these market demands, we would like to introduce the UL11527 AWG28 φ0.60mm single-core robot cable manufactured by OKI Electric Cable, which demonstrates excellent compatibility with various compact connectors.

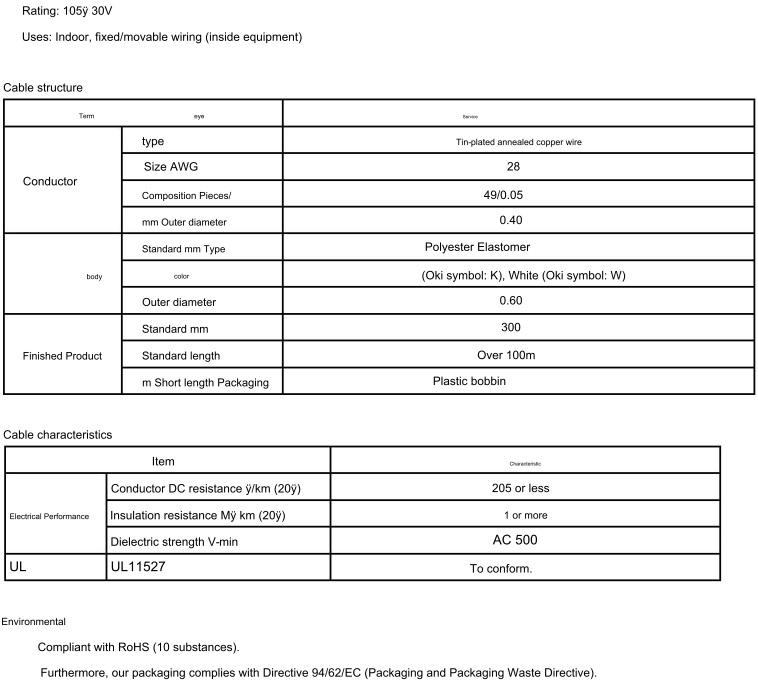

2. Product Overview: UL11527 AWG28 φ0.60mm

The UL11527 AWG28 φ0.60mm cable offers the following key features:

Conductor structure: 49 strands of 0.05mm wires (49/0.05) for excellent flexibility

Insulation outer diameter: Just 0.60mm for space-efficient routing

Insulation material: Polyester elastomer with high flex and heat resistance

Rated temperature: 105°C / Rated voltage: 30V

Certifications: UL compliant (UL11527), RoHS2 compliant

With its ultra-thin diameter and excellent bend resistance, this cable is well-suited for applications involving repeated motion or constrained spaces.

3. High Compatibility with Low-Profile Connectors

This cable is ideally suited for use with low-profile, small-pitch board-to-wire connectors such as:

JST ACH Series (SACH-003G-P0.2)

JST SUH Series (SSUH-003T-P0.15)

Hirose Electric DF52, DF57, DF58 Series

These connectors are designed for use in compact spaces and feature secure locking mechanisms. The UL11527 cable meets the size and flexibility requirements of these terminals, ensuring excellent crimpability and mating reliability, even in tight installations.

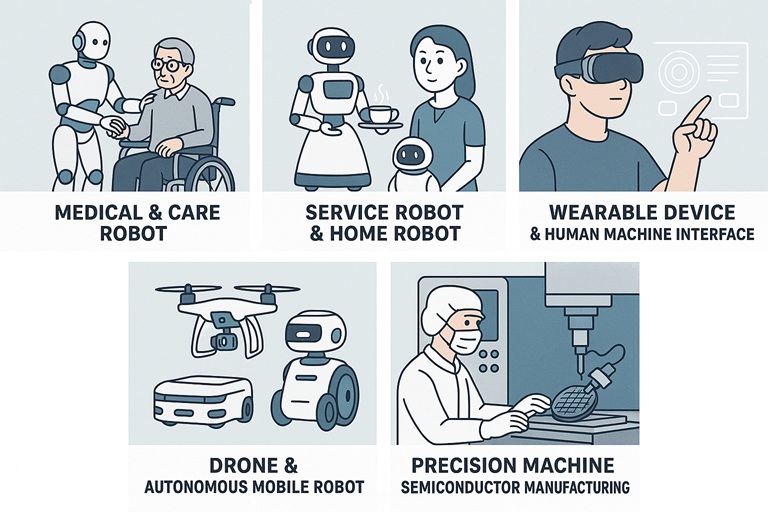

4. Target Applications and Future Demand

The combination of UL11527 cable and low-profile connectors is expected to be especially useful in the following areas, with projected growth in the next 5 to 10 years:

■ Automotive

Increasing electronic content in EVs, ADAS, and in-vehicle sensors is driving demand for compact and vibration-resistant wiring.

Ideal for battery management systems and space-limited ECUs.

■ Medical & Wearable Devices

Widely applicable in compact and portable diagnostic devices and wearable monitors.

Its high flexibility makes it suitable for on-body or textile-integrated sensors.

■ Robotics & Humanoid Systems

Suitable for joints and articulated parts where repeated flexing occurs.

The combination with locking connectors helps ensure stable connections during movement.

■ Drones / UAVs

Lightweight and flexible wiring is highly desirable for small drones and gimbal control systems.

UL11527 is well-suited for compact flight control boards and servo wiring.

■ Consumer, IoT, AR/VR Devices

Increasing need for fine wiring in smart glasses, AR headsets, and IoT sensors.

Excellent fit for dense internal connections where space and weight are critical.

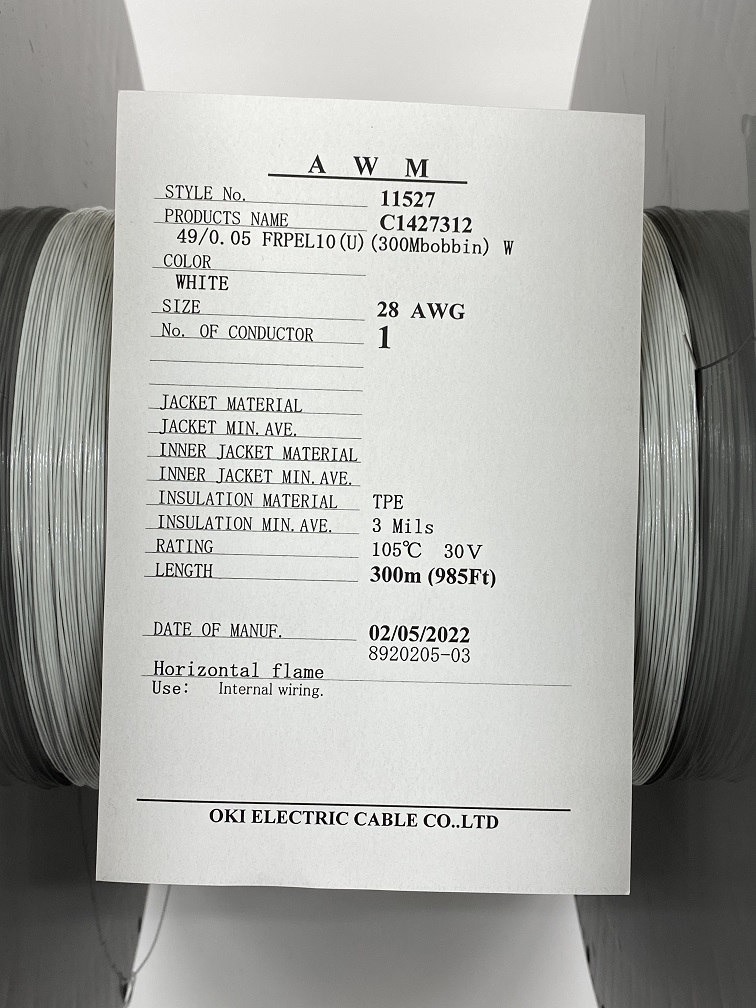

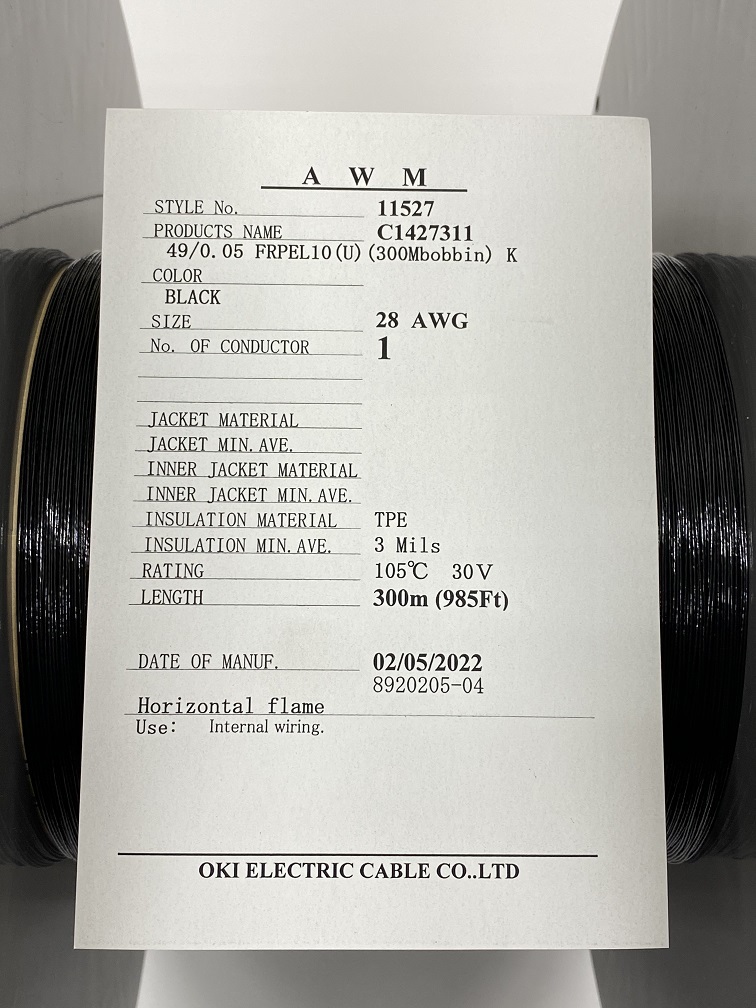

5. Flexible Supply for Prototyping and Small Lots

Cables with outer diameters of 0.60mm or less are generally produced in bulk quantities by many manufacturers, making small-lot procurement difficult for prototyping or R&D.

To address this, we offer the UL11527 AWG28 φ0.60mm cable in black and white, starting from just 1 meter. This allows for:

Rapid prototyping with minimal procurement hurdles

Reduced lead times and inventory risk

Flexible response to small-volume and specialized development needs

We hope this offering will support engineers working in early-stage development or evaluation.

6. Conclusion

The UL11527 AWG28 φ0.60mm robot cable demonstrates strong compatibility with low-profile, narrow-pitch connectors, and is highly suitable for use in compact and moving parts of next-generation devices. From automotive systems to wearables, robotics, drones, and consumer electronics, we believe this cable can contribute to reliable and space-saving wiring solutions.

We are pleased to offer small-lot sales and short delivery times to support your development activities. If you have any questions or would like to request samples or datasheets, please feel free to contact us.

◇Product page https://nisho-en.ocnk.net/product/168