Our product lineup includes Nagaoka Electric Wire's general-purpose curl cords, as well as highly flexible custom curl cords based on Oki Electric Cable's robot cables. This positioning us as a leader in addressing changing market conditions. While general-purpose products enjoy stable demand for retail facilities, office automation equipment, and light-load applications, it is high-durability and application-specific custom products that offer greater potential for future growth. This is because, as devices become more sophisticated, the operating conditions of moving parts become increasingly stringent, limiting the number of situations in which standard products are no longer suitable.

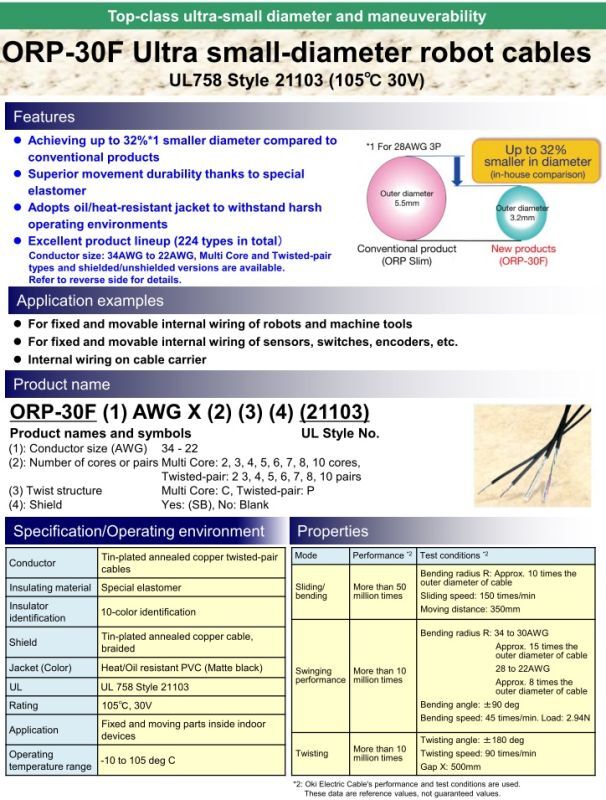

The widespread adoption of collaborative robots and compact automated equipment is a prime example. Labor shortages are driving investments in automation, even in small and medium-sized manufacturing companies. However, not all moving parts have strokes or loads large enough to warrant the use of cable carriers. For short reciprocating motions or limited ranges of motion, lightweight and flexible coiled cords offer design flexibility and cost advantages. Furthermore, as equipment becomes more compact, wiring space becomes more limited. A structure that naturally absorbs excess cable length is highly compatible with space-saving designs, contributing to internal organization and improved safety. Thus, the dual trends of equipment miniaturization and increasing functionality are supporting the adoption of coiled cords.

The medical and nursing care fields are also areas where stable demand is expected. Due to the aging population, the number of devices with moving mechanisms, such as height-adjustable medical chairs, rehabilitation support equipment, and home medical equipment, is on the rise. In these fields, safety and reliability are prioritized over wireless technology. For equipment requiring high power output or long periods of continuous operation, the reliability of wired power supply remains important. Furthermore, eliminating excess cords on the floor helps prevent falls and is a rational safety measure in medical facilities. A structure that can absorb excess cords using an extension mechanism offers clear advantages in terms of maintaining aesthetics while ensuring safety.

EV and battery-related equipment is also an area of interest. With the advancement of electrification, demand for maintenance equipment, inspection equipment, and evaluation equipment is expanding. These equipment often handle relatively high currents, making fully wireless deployment impractical from both a technical and safety standpoint. For equipment that repeatedly connects and moves over short distances, custom coiled cords with their elasticity and flexibility are potentially applicable. Robot cable-based specifications, in particular, offer increased design flexibility while ensuring durability against repeated bending and twisting.

Height-adjustable desks and adjustable furniture are becoming increasingly common in offices and homes. While electric lifting mechanisms have become commonplace since the spread of telework, wiring management remains a challenge. The degradation of aesthetics and the risk of wire breakage due to sagging wires directly impact product value. Curl cords, with their elasticity that naturally accommodates excess length, are a rational choice in terms of both design and functionality. While this market is not experiencing explosive growth, it is likely to remain stable at a certain scale.

Looking to the long term, the market is expected to move toward qualitative differentiation rather than quantitative expansion. While improvements in wireless technology and battery performance may replace some applications, wired power supplies remain essential for high-current applications, safety-standard compliant equipment, and long-term continuous operation in industrial applications. Furthermore, as AI advances, the number of sensors and small actuators will increase, resulting in an increase in the amount of wiring in moving parts. In other words, we expect a polarization to continue, with wireless advances advancing while high-reliability wired applications remain.

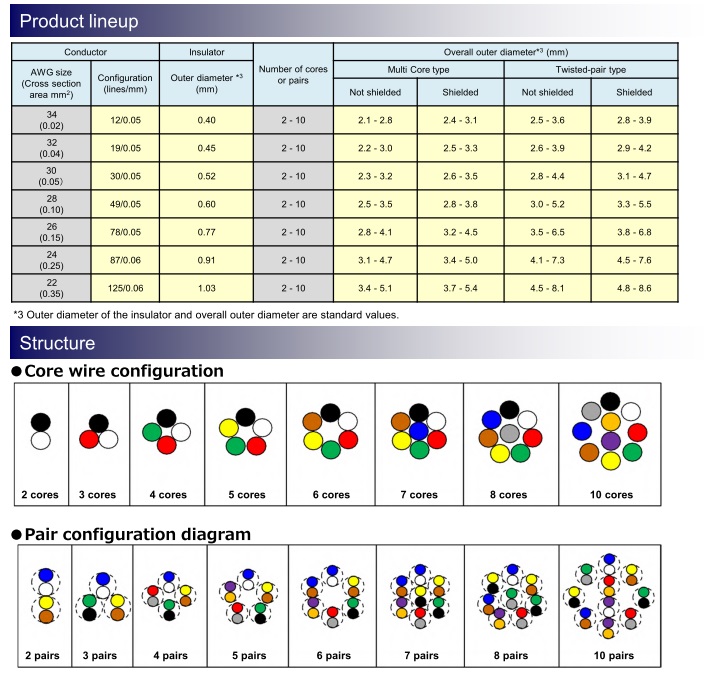

Amid this structural change, custom specifications optimized for each application will become increasingly important. Demand is likely to continue to grow, including hybrid specifications that combine power and signaling, high-reliability shielded types, and special-environment compatibility such as oil and chemical resistance and low dust generation. As equipment becomes more sophisticated, the need for specifications that cannot be met with standard products will expand. The idea of curling robot cables is a proposal that simultaneously satisfies the requirements for mobility and flexibility, and is an effective differentiating factor.

While curled cords are not eye-catching products, they are essential components that will be necessary as long as machines move in physical space. The possibility of a completely wireless society is limited, and wired devices will continue to play a role from the perspective of high output, safety, and reliability. Going forward, the market is likely to shift away from the mass supply of general-purpose products and instead become more focused on application-specific, high-value-added products. Having a system that can handle both general-purpose products and highly durable custom products will be a major advantage in adapting to this change. Being a niche market does not mean shrinking; rather, it is important to consider it as a market where expertise can be utilized when considering future developments.